Select your customer type to unlock tailored benefits.

Unwrapping the Universe of Pre-Rolls & Blunts

July 2, 2025

Unwrapping the Universe of Pre-Rolls & Blunts

July 2, 2025FROM HAND-ROLLED TO HIGH-TECH: EVOLUTION OF PRE-ROLL AUTOMATION

Presented by BLUNTD x XYLEM ROBOTICS

Centuries ago, traditional hand-rolled joints were introduced by rolling tobacco and other herbs in paper for an accessible, portable smoking option. During the 1960-70s cultural movement, rolling papers became a standard tool for cannabis users, but hand-rolling required time, skill, and consistency. As the cannabis market began to grow and professionalize, the limitations of hand-rolling became increasingly evident.

Hand-rolling posed challenges for large-scale production; namely, labor intensity, uneven burns, product inconsistency and hygiene concerns. Consumer expectations shifted toward convenience, consistency, and premium experiences. Automating the pre-roll production process became necessary to meet demand and expectations.

Initial machinery sought to replicate hand-rolling techniques but gradually evolved into more sophisticated systems capable of filling, packing, twisting, and sealing joints at scale. Early automation tools included vibration-based filling trays, manual tamping devices, and small rotary machines designed to improve speed and consistency over hand-rolling. These semi-manual systems still required significant human oversight but laid the groundwork for today’s fully automated, high-throughput pre-roll production lines.

Rise of Automation in Pre-Roll and Blunt Cone Manufacturing

The rise of automation for pre-roll and blunt cone manufacturing continues to transform the industry. Automation technology allows manufacturers to streamline production processes such as filling, packing, and sealing pre-rolls with automated systems like the Apehex—compatible with most conical joint tubes—or the BlackBird by RollPros—compatible with cigarette-style joints. These systems ensure uniform and consistent quality products.

When it comes to blunt filling systems, semi automated machines, such as the Futurola Knockboxes, are the industry standard. The operator fills the system with cones and loads the material, using a manual lever for initial filling and then packs down the material with an automated vibrational mechanism.

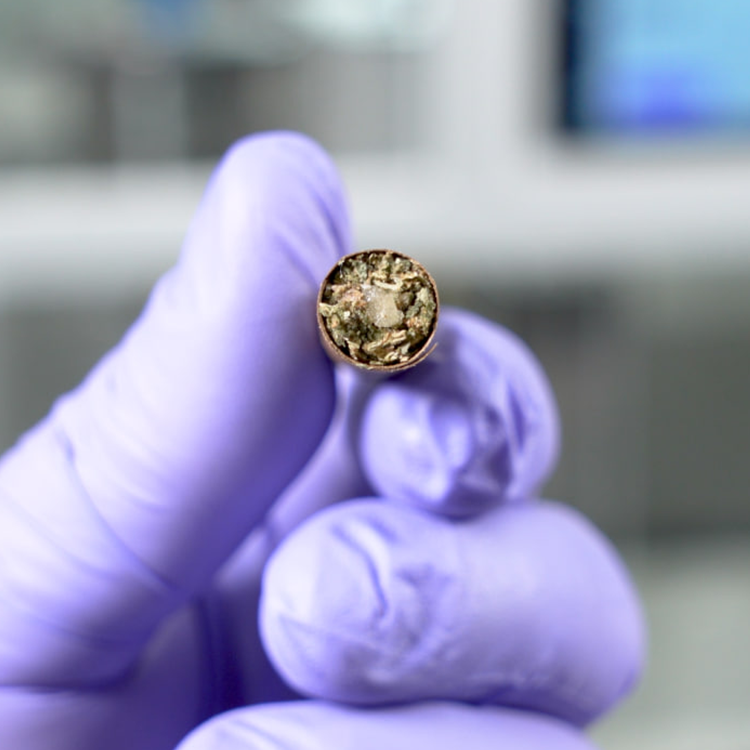

Brands are now taking the automated pre-roll and blunt filling process one step further, utilizing automation for the infusion process with systems like the Xylem Pre-Roll Infusion System. These automated infusion systems allow manufacturers to produce hash holes and infused pre-rolls at scale, at a rate of up to 700 units per hour with a single operator (a process previously done by hand).

Benefits of Automation for Cannabis and Hemp Producers

As mentioned throughout this article, automating the pre-roll production process offers significant advantages for cannabis and hemp producers seeking to scale efficiently and competitively. A skilled hand-roller can typically roll 100-200 pre-rolls per day, depending on skill level and product quality. Transitioning to an automated pre-roll machine increases production output to 500-1000 pre-rolls per hour. By increasing output, automation enables higher production volumes to meet growing demand without sacrificing turnaround time.

Automated machinery vastly improves consistency concerns by ensuring uniform fill, pack, and burn quality across every unit Advanced machinery models fill, weigh, compact, twist or crimp, and sometimes even package the pre-rolls.

Reduced reliance on manual labor cuts operational costs while minimizing human error. This also mitigates the issue of human contact with the products, which previously posed hygiene and quality control concerns. Finally, automation opens the door for enhanced branding opportunities, allowing producers to incorporate custom cones, filters, and packaging elements that strengthen brand identity and elevate shelf appeal.

Choosing the Right Automation Solution

In the ever-evolving cannabis industry landscape, selecting the best automation solution for your business can significantly enhance efficiency and product quality. There are a few essential factors to consider when choosing the equipment to streamline your production process:

1. Product format and throughput needs

- Determine the type of pre-roll wrap, size, and your desired rate of production to narrow down your equipment options

2. Customization and expansion capabilities

- To prepare for business scalability and demand increases, plan for additional, new SKUs that can be made or customization options with the system you choose

3. Initial Investment vs. Long-Term Savings

- Analyze upfront costs with revenue potential. While initial automation technology costs can be intimidating, pre-roll solutions lead to reduced manufacturing errors, dependable product, and repurposed labor and expenses.

4. Return through increased orders and consistency

- Reliability of a consistent, quality product leads to increased customer satisfaction, repeat customers, and more orders!

Popular Cannabis Automation Manufacturers and their equipment

Below are some of the most advanced pre-roll automation systems and solutions, and their features for hemp, cannabis, and concentrate-infused pre-rolls:

For paper pre-roll and blunt wrap pre-rolls:

- Canna RocketBox Pro 2.0

- Futurola Knockbox 3

- King Kone

- ActionPac RollMaster420

- RollPros Blackbird

- PreRoll-Er Weed Good Pro

For infusing pre-rolls and blunts:

- The Xylem Robotics Pre-Roll Infusion Machine is fully automated and customizable to your business’s SKUs, requires one operator, and can infuse 500-700 pre-rolls of ANY format per hour (depending on the type of material you’re infusing pre-rolls with).

- The Astro Infuser Warp Speed Pre-Roll Infuser drops a dollop of concentrate into paper cone pre-rolls and then pulsates up and down to push the material through the pre-roll and is said to infuse 2,880 pre-rolls an hour

- The Thompson Duke – MPM-300 is semi-automated with manual controls (foot pedals + a handheld gun) and is estimated to produce 500 pre-rolls per hour.